Hi, My name is Josh Hausler, I am an enthusiastic and easygoing individual whose career journey so far has been guided by a commitment to constant self-improvement and a strong desire to contribute positively to any team or project I’m a part of. I have excellent communication skills, am a critical thinker with strong problem-solving abilities, and exhibit self-discipline and efficient teamwork skills. My compassionate and empathetic approach allows me to build meaningful relationships, and my willingness to learn new things ensures I stay ahead of the curve.

Joshua Hausler

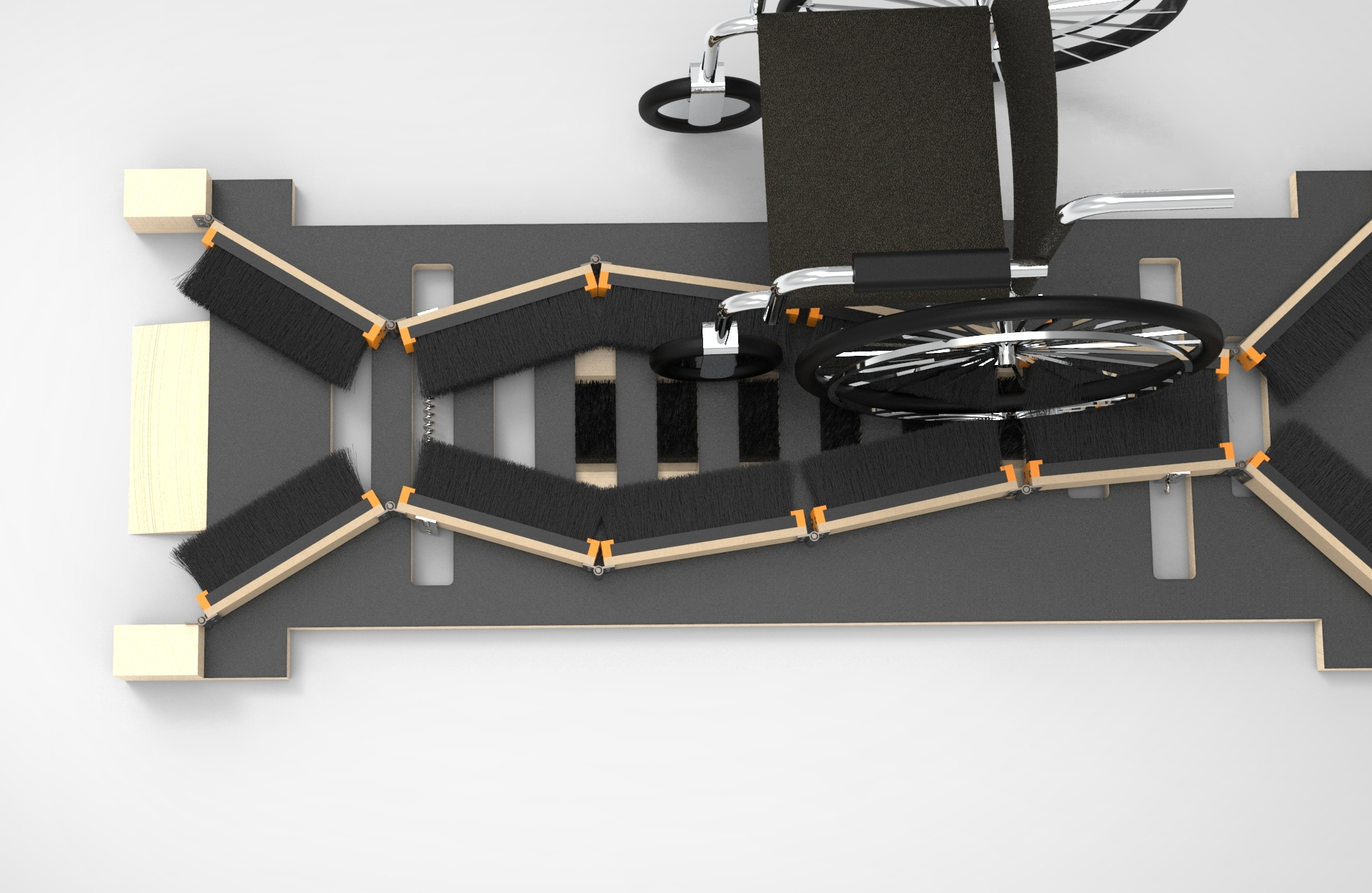

Device In it's natural habitat

The device is designed to be utilized in various settings—whether it's positioned on, before, or after safety ramps, enhancing accessibility both on residential and commercial fronts. Moreover, it's suitable for placement on back decks, aligning with the intended user's preference for this product's location

Over view of device in used (Allowing for offset wheel)

One of the primary challenges faced in this project revolved around devising a solution that accommodated various wheelchair designs, particularly those with off-set back wheels, a prevalent feature in the majority of wheelchairs. To address this concern, a novel approach was developed—an adaptive spring-loaded brush mechanism. This innovative solution was engineered to dynamically conform to the diverse sizes, shapes, and alignments of the wheels, ensuring a more thorough and effective cleaning process. The implementation of this solution not only catered to the intricate specifications of different wheelchairs but also significantly improved the overall cleaning performance

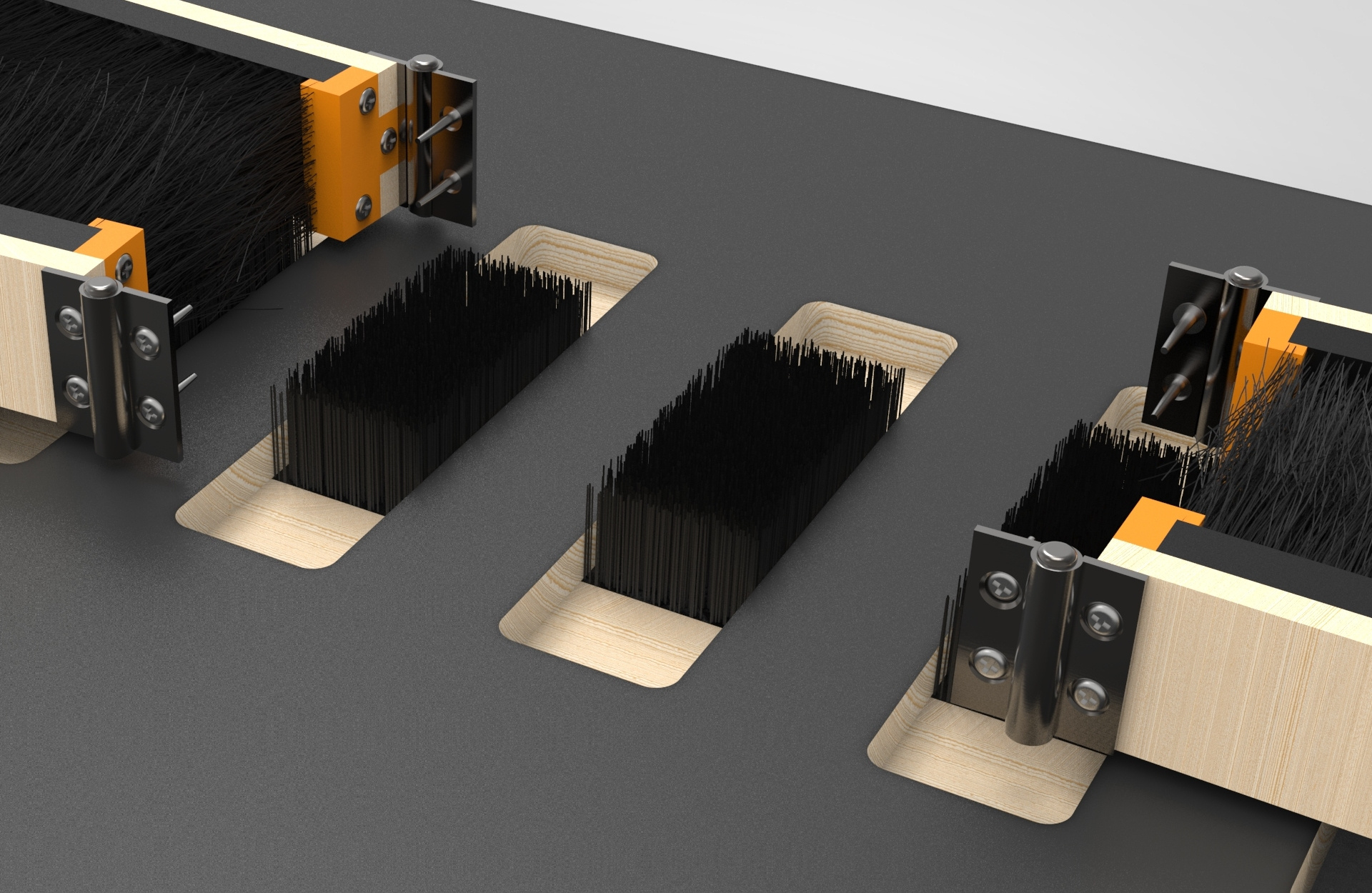

Base Bush and CNC

The deliberate gaps and channels within the device not only facilitate the integration of mounted high-density, thick-based brushes for a more robust cleaning approach but also serve the essential function of preventing dirt accumulation on the device's surface. This design element enables a comprehensive cleaning method, allowing the brushes to penetrate between the grooves and treads of the wheels effectively

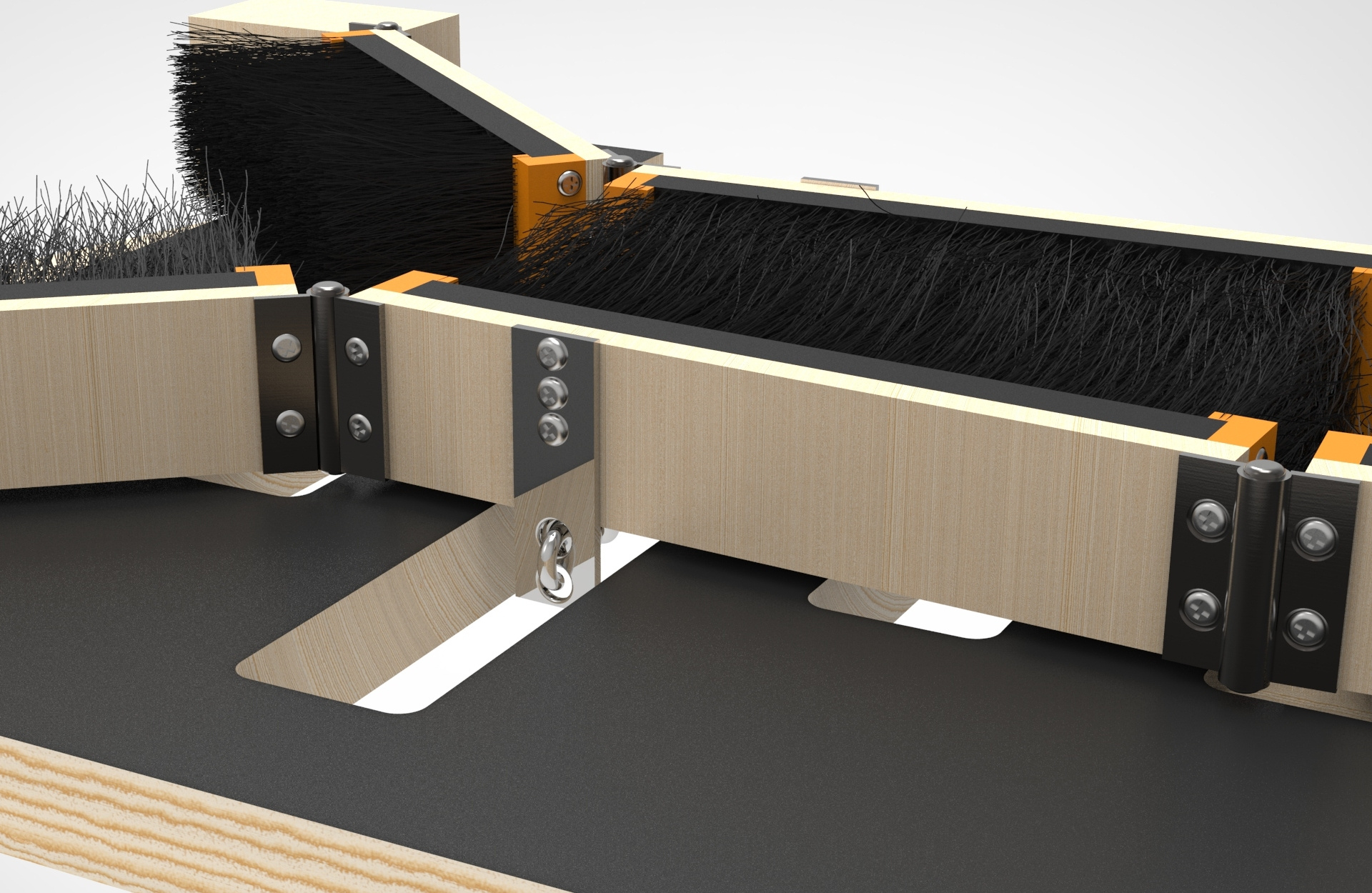

Spring and Brackets

This image offers a detailed, close-up perspective of the spring system, which defines the structure of the device, along with the hinges responsible for holding the brush subassemblies together. Notably, the CNC tooling is discernible in the base, evidenced by the visible radii depicted in the image. These features highlight the intricacies of the spring system, hinges, and CNC tooling, showcasing the precision and design elements crucial to the construction of the device

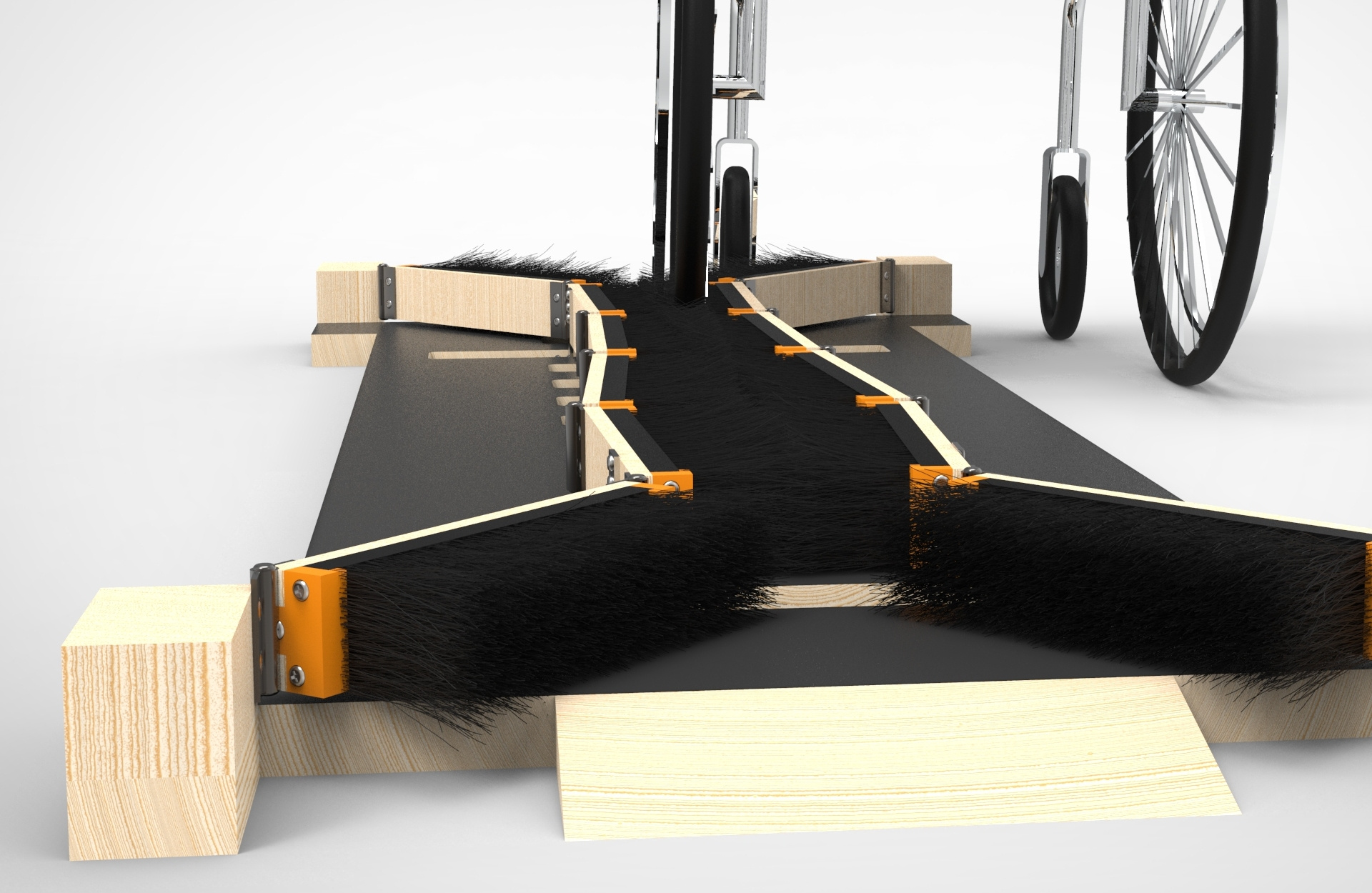

Just a Nice Render

This render presents the device in all of its glory. It highlights the usage of the recommended components that are not only cost-effective but also require minimal post-processing, with the majority of parts directly sourced from stores. The device boasts a range of easily accessible and affordable components, aligning seamlessly with the industry partners' objective of creating accessible and affordable assistive technology for all. This emphasis on cost-effective and readily available components underscores the commitment to ensuring accessibility without compromising on quality, adhering to the mission of making assistive technology widely attainable.